Quality is of prime importance in any aspect of business. In the garment industry, quality control is practiced right from the initial stage of sourcing raw materials to the stage of final finished garment. And the quality of the garment have a direct impact on supply chain performance and customer’s expectation.Therefore, it’s crucial for importers involved in fabric manufacturing in China .

In this post , I’ll answer the question ” What is garment quality control ?” and I ‘ll explain how we can manage garment quality effectively.

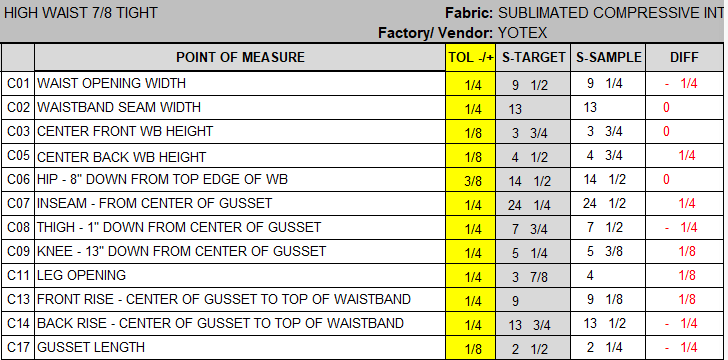

1. Set clear tolerances for garment measurements.

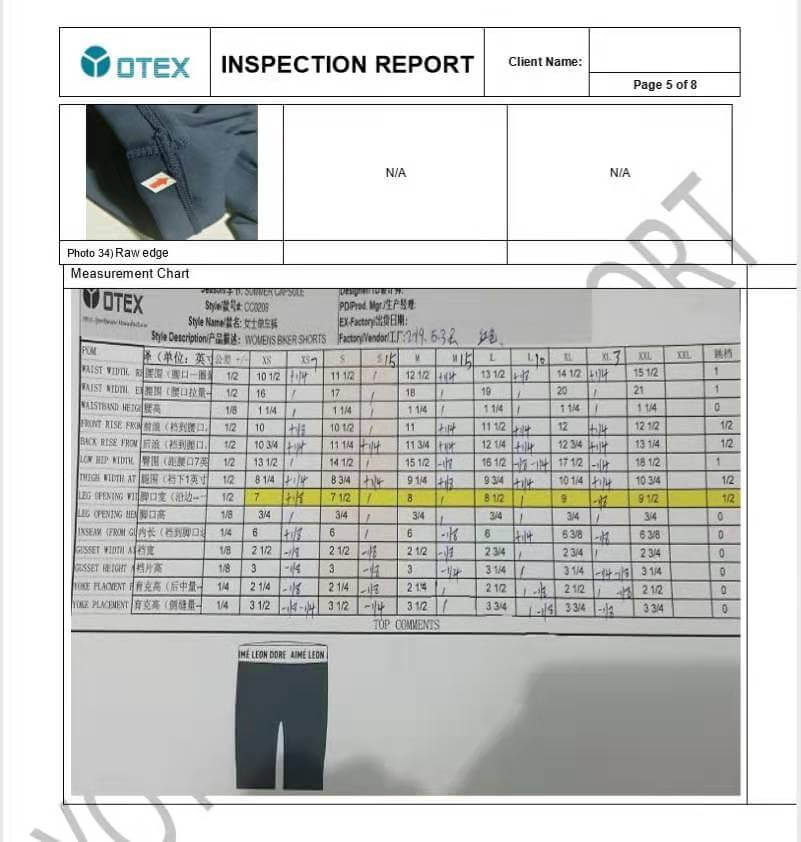

Measuring garment dimensions is a critical aspect of garment quality control. Most consumers care about the fit and comfort of a piece of clothing more than any other factor. But garment measurements can also be one of the hardest aspects of garment quality to manage with your supplier. Garments are typically individually handsewn. When creating garment specs, set a tolerance for each point of measurement that allows for a small margin of error. And provide this list of tolerances to both your supplier and your QC team to ensure goods are produced and inspected to your requirements.

Specify each point of measurement in a spec sheet for garments

Your garment specs should included:

- Each point of measurement: It depends on the garments we are manufacturing. All detailed measurement should be listed in spec.

- Standard measurements for each size: The measurement norm should be illustrated clearly, such as seam to seam or edge to edge.

- Tolerance for each point of measurement: There is a range in the tech pack above or below your standard measurement that can be accepted, like TOL -/+.

2. Manage a quality control during production.

Each step in the garment production process is vital to the overall quality of apparel products. The production of quality clothing includes cutting, assembling, pressing and other finishing procedures, and final inspection. The following section describes the quality control of apparels during various production processes.

- Spreading and cutting defects: Proper care should be taken to avoid any mistakes during spreading, otherwise, it will result in improperly cut components. For cutting, precision is needed to cut accurate pieces that will fit together during the assembly process.

- Defects in assembling: including defects with both stitches and seams

- Defects during pressing and finishing: These final preparations include pressing garments to help set seams and finish garment shaping.

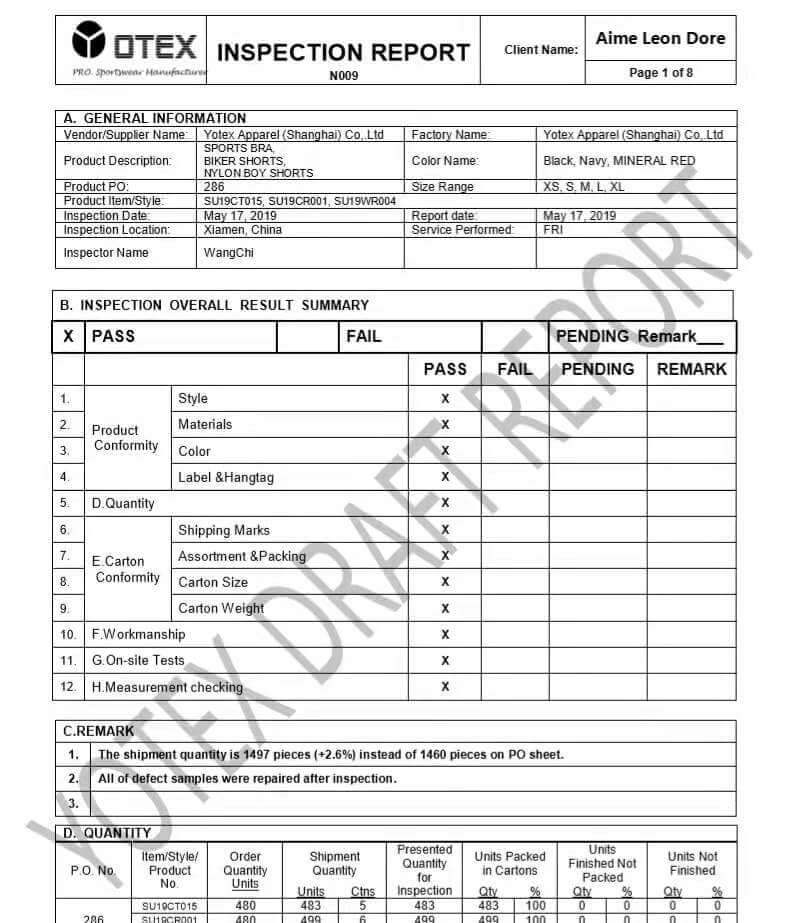

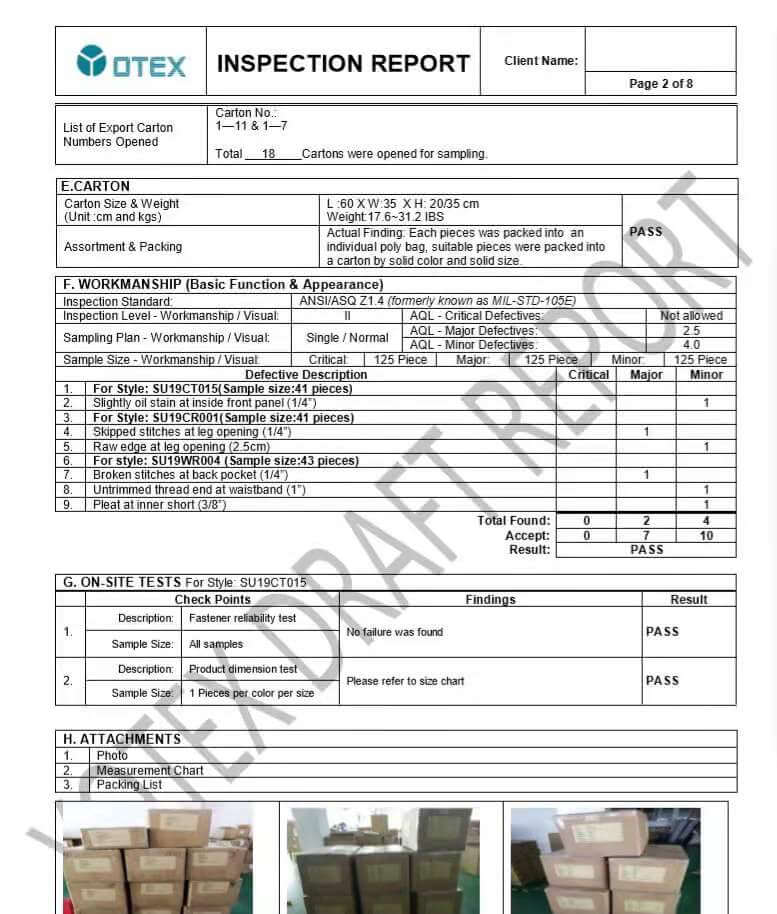

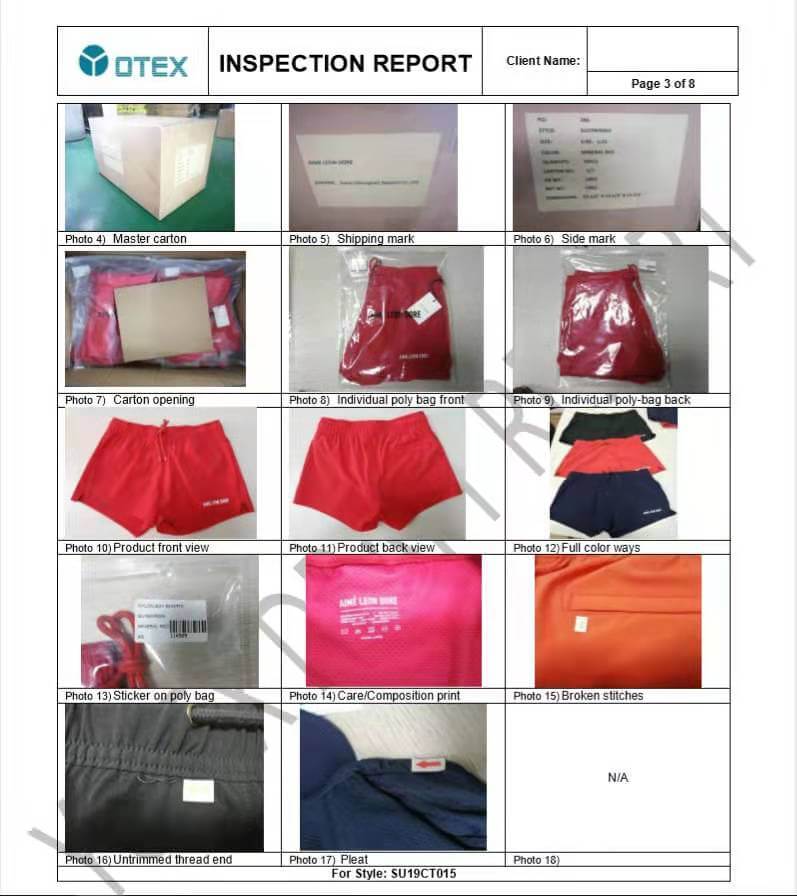

3. Conduct a inspection during pre-shipment garment inspection.

A professional inspection report can ensure you will receive the garment within you and your customer’s expectation. Because any defects can be tested and corrected through inspection and will be presented on garment checking table .

It is to be recalled that YOTEX APPAREL has own specific inspection report.

In a word , we can see that managing quality control in apparel industry is really significant. We can say that quality control in terms of apparel manufacturing, pre-sales and posts sales service, delivery are essential for any garment manufacturer, trader or exporter. As a apparel manufacture, YOTEX APPAREL always works hard to get better.