Printing is a timeless fashion element in the fashion trend. It is one of the indispensable processes in the field of apparel manufacturing. Yotex Apparel, as a sportswear and activewear manufacturer with up-to-date technology to catch up the trends, write this article about how to use printing technology on a garment.As we know,it become a chic trendy that people follow a variety of exquisite prints on their garments, whether it is used daily, or only a distant view of the art, printing has its unique charm.

Come and enjoy the printing process together today.

Traditional screen printing

1.Water printing

It is one of the most basic printing processes in the screen printing industry. It works like dyeing, except that it dyes a certain area of the fabric into the color required for the registration position.

The advantage is that it can be printed on almost all the light-colored fabrics without affecting the original texture of the fabric. It can be applied widely, the registration fastness is very good, and the better effect can be printed at a relatively low price; the limitation is not available on all dark fabrics and its covering power and sense of feeling is not so strong .

2.Rubber printing

The rubber printing process uses a special chemical gel that blends seamlessly with the dyestuff. The dye acts firmly on the fabric through the medium of the gel, overcoming the limitations of the water printing.

It is characterized by printing for various color depths and materials. It can be printed on blended fabrics of cotton, hemp, viscose, polyester, nylon, polypropylene and various fibers. It can also be used on leather, artificial leather and other materials. Printing, which can be used for fluorescent printing, inkjet printing, burnt printing, electrostatic flock printing and others.

The biggest advantage of the rubber printing process is its wide application, beautiful color and high degree of reduction. However, its printing process is more complicated than the water printing , and the cost is relatively high. Due to its certain hardness, it is not suitable for large-area field and pattern.

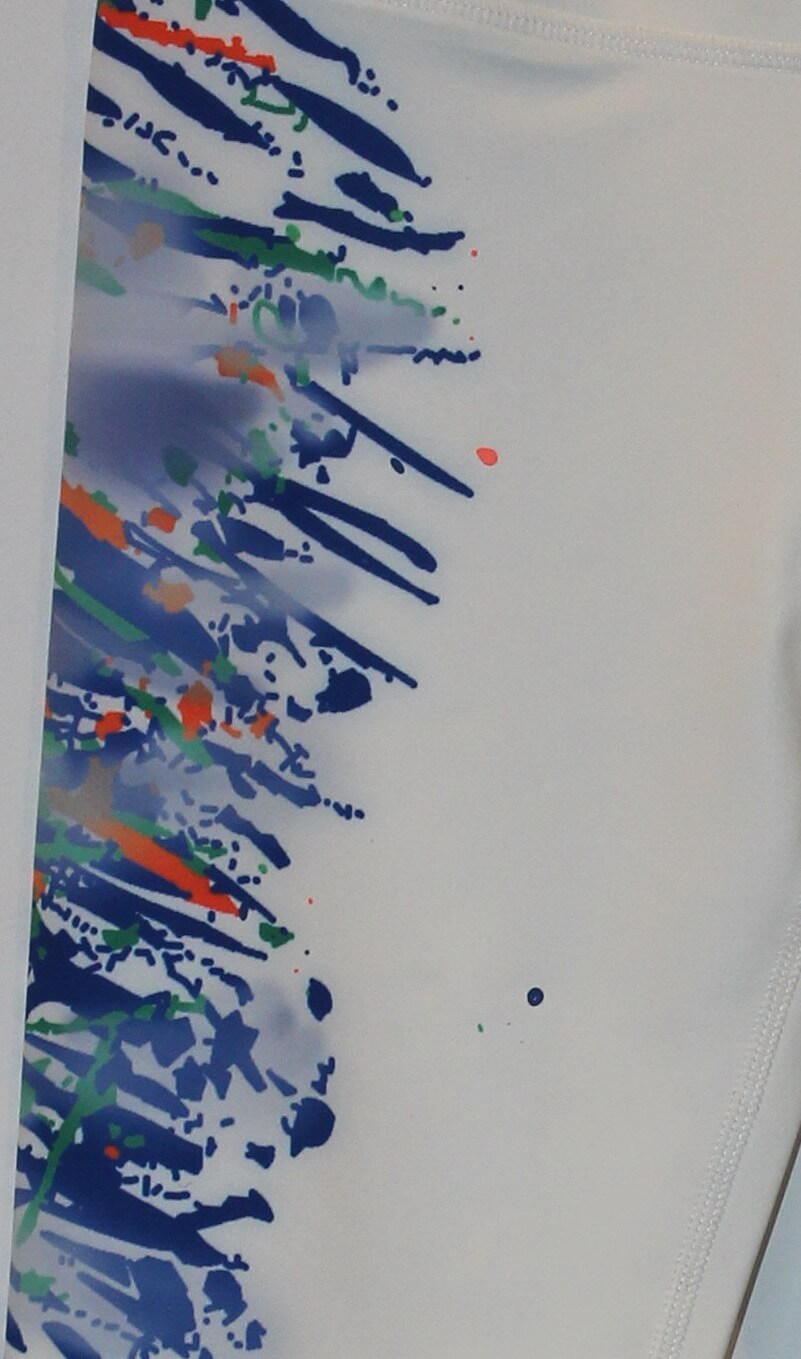

3.Ink printing

At first glance, the ink printing is not much different from the rubber printing, but when the rubber is required to be printed on a smooth fabric such as a windbreaker, the color fastness is usually poor, even it can be scraped off by using nails vigorously, but ink works well. Therefore, when making a windbreaker, it is usually printed with a vivid image and beautiful color . There has been a wave of portrait prints on the market till now. That clear and super-realistic printing is usually only printed by ink. Sometimes gold and silver powder can also be sprinkled on the ink, which will enhance overall visual effect.

4.Pigment printing

Pigment print is used to define any type of printed image that uses strictly pigments, rather than dyes.

The advantage is it can be applied on natural and synthetic fibers and it is a easy task for garment printer.

Digital printing

Digital printing refers to methods of printing from a digital-based image directly to a variety of media. It usually refers to professional printing where small-run jobs from desktop publishing and other digital sources are printed using large-format and or high-volume laser or inkjet printers.

We can mainly divide digital print into direct print and sublimation print.

1.Direct print

It is to spray the dispersed ink directly onto the fabric. At present, the direct injection technology is applied to the process of pure cotton printable fabric.

2.Sublimation print

It is a special sublimation ink printed on a special transfer paper by a photo machine, and then the color of the ink is colored in the fabric by high-temperature divergence technology. The transfer paper is a one-time product, which can only be discarded after one use. Personally, it is considered to be a waste of cost.

Fabric suitable for sublimation printing includes chiffon yarn, oxford cloth, polyester cloth, polycotton cloth, quilting fabric etc.

What’s more,we could also use custom printing on above fabric, such as specific picture, writing, or enterprise’s logo and other popular elements, which is feasible to meet client’s personalized demand.

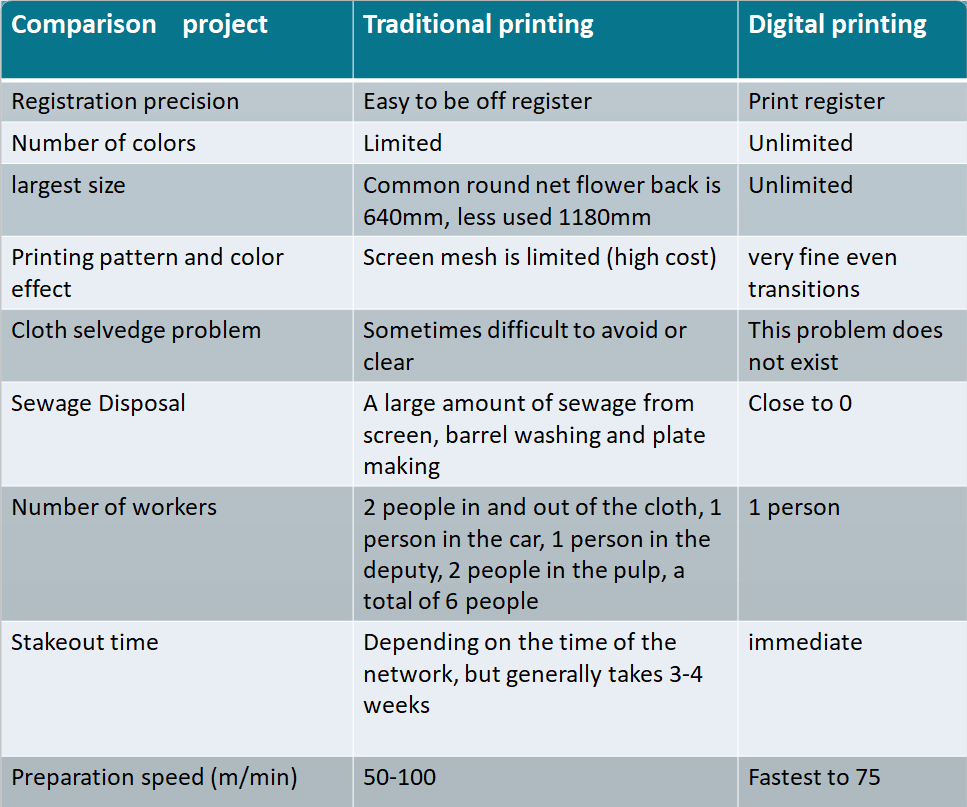

Now, let’s make a summary and compare digital printing with traditional print.

some difference between traditional print and digital print , see table.

3.Others.

Beyond these two kind printings, there are still some other significant printing technology playing unique roles in this mysterious printing world.

Sequin printing on velvet fabric.

Emboss print on vinyl upholstery fabric.

Foil Printing on recycled fabric.

Ombre print on lycra fabric.

In a word, as a professional activewear and sportswear supplier,we are always on the pursuit of printing effect and finished hand feeling, as well as the speciality of the textile itself when we choose the printing method.

The way of printing should be advancing with the times, in line with the aesthetic and quality requirements of the times, and constantly innovate and develop.

No best, only better.